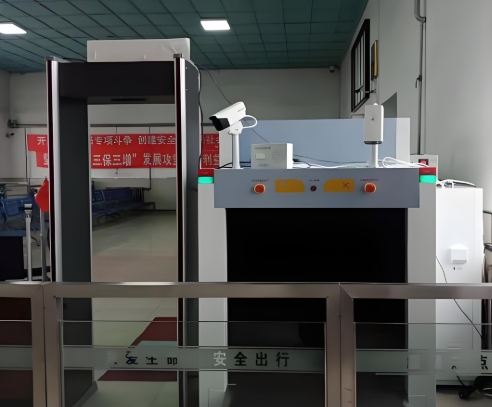

Securina X-ray Baggage Scanners: Maintenance and Safety Guidelines

An X-ray baggage scanner is a high-tech electromechanical product. Therefore, users need to not only understand the machine's technical performance, structural principles, and operating procedures but also be proficient in daily maintenance and upkeep to fully utilize its effectiveness, extend its lifespan, and ensure the safety of both the equipment and personnel.

1. Daily Maintenance and Upkeep

To ensure that the actual performance of the security X-ray scanner matches the technical specifications in the manual, regular inspections and necessary adjustments should be performed. Maintenance work must be carried out by trained personnel who have been recognized by the company. During hardware maintenance, the device must be powered off before any work begins.

1.1 Normal Maintenance

- The baggage screening machine should be installed in a well-ventilated, dust-free, and dry environment, avoiding high temperatures, humidity, and direct sunlight exposure.

- During maintenance, dust should be removed from the security inspection system using a brush and vacuum cleaner.

- If any components or wire terminals are loose, tighten them immediately.

- If components are corroded, replace them if necessary.

- If components are damaged, identify the cause, fix the issue, and replace the components. After replacement, adjust the related parameters before using the device again.

- Foreign objects or liquids must not enter the X-ray inspection scanner during maintenance to prevent leakage or accidents.

1.2 Specific Maintenance Tasks

- Check the power indicator: When the airport security scanner is powered on, the green light should be illuminated.

- Check the X-ray indicator: The red light should be on when X-rays are emitted by the X-ray baggage scanner.

- Check the emergency stop button: Pressing it should immediately cut power to the device. If the button is not reset, the device cannot be restarted.

- Check the key switch: Only after the key switch is turned on can the start button operate the device. The X-ray stop button should cut power to the X-ray inspection system. If the key switch becomes unresponsive, it should be replaced.

- Check the touchscreen display: The image should adjust according to the zoom and image processing buttons.

- Check the light barrier: Place an opaque object on the conveyor belt, and ensure the X-ray luggage scanner can be activated. After turning off the device, clean the light barrier’s lenses and the glass installed on the channel walls.

- Check the motorized rollers: Press the corresponding button to check if the roller moves in the specified direction and stops. The roller should operate with normal noise and no oil leakage.

- Check the detector box and collimator limit switches: When any cover is removed, the X-rays should stop emitting.

- Check conveyor belt alignment: Ensure the conveyor belt is aligned with the motor in the baggage inspection system.

- Check the ventilation openings: Ensure they are not blocked, and clean any dust on them.

2. Safety Precautions during Maintenance

- No foreign objects or water should enter the device during maintenance to avoid equipment damage or safety hazards.

- The device contains many components with a 220V working voltage. Routine maintenance must be performed when the power is off. If working with live equipment, only trained personnel should perform the work, and appropriate electrical safety measures should be in place.

- The device contains delicate electronic components. Before maintenance, prepare for static discharge protection.

- The device has lead shielding to prevent X-ray leakage. During maintenance, it’s best to wear cotton gloves, and if gloves are not worn, wash hands immediately after handling the X-ray baggage scanner.

- Before powering on, carefully check all connections to ensure proper wiring without any mistakes or short circuits.

- Before activating the X-rays, ensure the cover is secured to prevent personal harm from exposure.

3. Replacing Rollers and Conveyors

Before replacing the rollers and conveyor belt:

- Turn off the power and disconnect the motor cable from the security screening equipment.

- Remove the outer cover plate and unscrew the conveyor from the frame.

- Loosen the tension bolts and the belt to replace the motorized rollers or the alignment rollers.

Replacing the Conveyor Belt:

- Cut and remove the damaged belt.

- Process the new belt according to the original belt length at the belt factory.

- Perform cold bonding on-site for the new belt.

4. Replacing and Adjusting the Light Barrier

To replace and adjust the light barrier in the airport baggage scanner:

- Disconnect the power and open the outer cover.

- Disconnect the light barrier cable.

- Unscrew the two fixed bolts of the light barrier.

- Replace the light barrier and adjust its position by moving it up or down, ensuring it is securely fixed.

- Weld the connector to the cable exit according to the blueprint.

- Reconnect the cable and close the cover.

- Power on the security inspection system, test with an opaque object on the conveyor belt, and ensure the X-ray inspection scanner is activated.

5. Replacing and Adjusting the X-ray Source

Follow these steps when replacing and adjusting the X-ray machine for security:

- Power off the system and remove the outer cover.

- Disconnect the cable from the X-ray source.

- Remove the fastening screws securing the X-ray inspection system.

- Remove the limit blocks and loosen the adjustment bolts.

- Take out the old X-ray source.

- Follow the reverse steps to install the new X-ray source, but don’t tighten the screws or limit blocks initially.

- Power on the system, adjust the X-ray baggage scanner using the provided adjustment screws and handles.

- Tighten the fastening screws and limit blocks after adjustment.

6. X-ray Tube Conditioning

X-ray tube conditioning aims to reduce the failure rate of the X-ray luggage scanner, extend the life of the X-ray tube, and improve the overall reliability of the system. If the equipment has been unused for more than six months or subjected to transport or vibration, it is crucial to follow the proper conditioning procedure. The procedure includes:

- Power-on process

- Initial adjustment

- Conditioning

- Final adjustment

7. Common Failures and Troubleshooting

This section covers common failures, their causes, and troubleshooting methods. Maintenance work should only use parts and components provided by the manufacturer. The company is not responsible for damages caused by unauthorized repairs or the use of third-party parts.

All repairs and adjustments should be performed by qualified personnel. The device should only be powered on after all circuit boards are correctly inserted. Always turn off the power when removing or inserting printed circuit boards.

7.1 Power Failures

- System does not power on: Check local power supply, key switch, fuses, and emergency stop button.

- Power indicator does not light up: Ensure the device is powered on and check the power cable connections.

- System powers on but has no other functionality: Check electronic controllers and power supply connections.

7.2 System Control Failures

- Conveyor belt not running: Check for faulty wiring or damaged motors.

- Conveyor belt running continuously: Replace the electronic controller or reset the industrial computer.

7.3 X-ray Source Failures

- X-ray source not emitting: Ensure objects are placed on the conveyor, the light barrier is connected, and the X-ray controller is powered.

7.4 Image Display Failures

- No image during baggage inspection: Check connections and replace the control board or light barrier.

8. Storage Conditions, Storage Period, and Precautions

When disassembling the X-ray baggage scanner for shipment, follow the reverse steps for reassembly. The system should be stored in a clean, dry environment, avoiding overheating or high humidity, which can damage the system components. If the device is unused for a long period, it should be stored in its original packaging.

Storage Conditions:

- Storage temperature: -20 to +60°C (non-condensing)

- Humidity: 20% to 95%

For long-term storage, ensure the storage facility is clean, dry, and well-ventilated. The relative humidity should not exceed 80%, and the device should be stored in its packaging box.

We are a professional manufacturer of high-quality X-ray baggage scanners and security screening systems based in China. With years of expertise in the field, our company specializes in designing and producing cutting-edge X-ray inspection systems for security applications in airports, transportation hubs, government facilities, and critical infrastructure worldwide.

Our X-ray baggage scanners provide advanced detection technology, ensuring efficient, reliable, and safe screening of baggage, luggage, and parcels. Designed with the latest X-ray detection technology, our systems deliver detailed and accurate imaging, capable of identifying threats such as weapons, explosives, and contraband materials. Whether you need a compact security X-ray scanner for small areas or large-scale baggage inspection systems for high-volume settings, we offer tailored solutions to meet your specific needs.

What sets us apart is not only the advanced technology embedded in our products but also our commitment to customer satisfaction. We offer comprehensive technical support, training, and after-sales service to ensure that your airport security scanners and X-ray inspection systems operate at their peak performance. Our dedication to innovation and quality ensures that each of our products is manufactured with precision, adhering to international safety standards.

If you are looking for a reliable supplier of baggage screening machines, security inspection systems, or advanced baggage screening technology, look no further. We invite you to get in touch with us to discuss your specific requirements. Whether for a new installation or system upgrade, our team is ready to provide you with the perfect solution to enhance your security operations.

Contact SECUEINA today to learn more about our high-performance X-ray baggage scanners and discover how our products can help secure your facility.