How to install and operate the security screening machine x-ray baggage scanner SA6040?

1. When you receive the goods, the standard export packaging was is as follows:

2. After opening the package, check the goods and their accessories. The standard set of SA6040 includes:

--1. 17-inch display x 1unit

--2. Technical use keyboard and mouse x1unit

--3. Operation dedicated keyboard x 1unit

--4. Manual and tool kit x 1unit

--5. Exit extension 50cm table x1unit

--6. Scanner body x1unit

3. Installation of SA6040 Airport security scanner:

Take out the monitor, keyboard and mouse for operation, and find the main control line and several ports extending from the upper part of the machine. Find the corresponding ports to connect the keyboard monitor and mouse, and then connect the DC plug (conventional 220V/50HZ power supply) to the local power supply. It can be plugged in and used, and the installation is very simple. The bottom of the machine is equipped with four movable wheels to facilitate the adjustment of the equipment to a suitable position on the ground.

4. Operation of SA6040 Security X-ray Inspection Equipment:

Inspection before Boot:

Step 1 Check whether the cable connections of the equipment power supply are in good condition; Check whether the equipment power supply is grounded reliably; whether the Emergency Stop button on the external cover plate is pressed down, if yes, please rotate it clockwise to reset it; whether the Emergency Stop button on the special keyboard of the equipment is pressed down, if yes, please rotate it clockwise to reset it; whether the keys of the special keyboard work properly. The connection position of the power supply is shown in Fig 4.1 below:

★ NOTE

If you find the damaged cable sheath, failure of the Emergency Stop button or unsmooth special keyboard, please stop operating the equipment and contact the local after-sales service department.

Step 2 Check whether the lead curtains at the channel inlet and outlet which are used to prevent the X-ray leakage are in good condition; the door curtains should be free from the obvious gaps and obvious damage

★ NOTE

If there are the excessive gaps between the curtains or the lead curtains are seriously damaged, please stop operating equipment and contact the local after-sales service department.

Step 3 Check and make sure that the surface of the belts should be no cracks, and a certain distance should be reserved between the conveyor belt edge and the guard boards on two sides; check whether belts are deviated or stuck.

★ NOTE

If the conveyor belt position obviously deviates from the channel center (its edges are stuck in the guard boards on two sides) or the belt has insufficient tension (the conveyor surface is loose), the operator should adjust the conveyor position under the guidance of professionals, or read the maintenance manual carefully.

Step 4 Check whether there are some goods in the equipment channel, if any, please clear it out of the channel.

One-key boot: Turn the key, press the next start button, wait for the system to automatically start and enter the operation interface.

Step 1 Plug the power cable plug into the power supply socket on site to ensure the normal power supply.

Step 2 Insert the key into the key switch  of the special keyboard and rotate it clockwise by

of the special keyboard and rotate it clockwise by

90°to “ON” position; then press and hold the power button  for about 1 second until the power indicator lights of the equipment

for about 1 second until the power indicator lights of the equipment  and special keyboard

and special keyboard  are on, and wait for the system boot.

are on, and wait for the system boot.

Login

Step 1: The system will will automatically login as the default user.

★ NOTE

If the system disabled the automatic login function, then you need to select a user and enter the login password before login.

Step 2: After login, the system directly enters the XBIS software to display "Clear the Channel" , then please select a way to clear the channel, as shown in Fig 4.2.

Choose the way:

l If there are goods in the channel, please click the button  /

/  on the interface or click button

on the interface or click button  /

/  at the special keyboard , then the conveyor will run in the relevant direction and the goods in the will be cleared out of the channel; click

at the special keyboard , then the conveyor will run in the relevant direction and the goods in the will be cleared out of the channel; click  on the interface or click the button

on the interface or click the button  of the special keyboard to stop the conveyor.

of the special keyboard to stop the conveyor.

l After clearing the channel or when the channel no need to be cleared, you can click  on the interface or press key

on the interface or press key  on the special keyboard to turn off the clearing channel interface.

on the special keyboard to turn off the clearing channel interface.

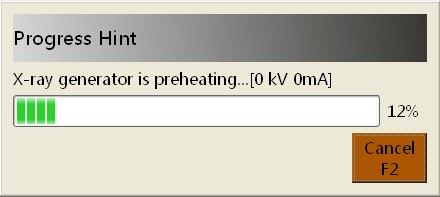

Step 3: If the machine is not used for more than 24 hours, then when the system boot up for the first time, the system will get into a preheating process to make the X-ray generator ready, Please wait about 1-20 minutes until the preheating is finished, the system will enter the main interface .

Step 4: After the preheating process is over, the system directly enters the main interface.

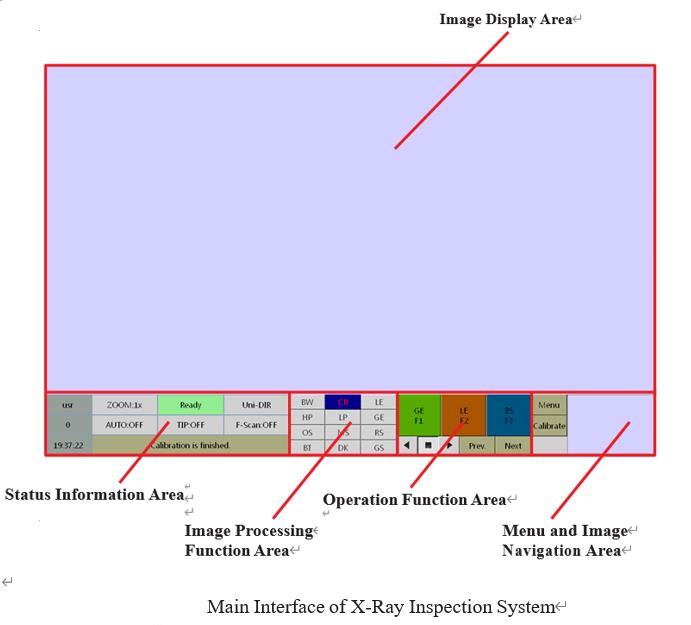

System Main Interface:

Here is the main interface, as show in Fig 4. 4.

More details about operation welcome send email to info@securinadetection.com to get complete user manual.

Precautions:

1) Only properly trained personnel can install and use the security x ray inspection machine.

2) Only technicians can remove the cover or protective parts during maintenance.

3) Do not use X-ray baggage inspection equipment outdoors.

4) The security baggage scanning machine must work under the specified working voltage. The voltage used must be checked before the equipment is used.

5) The airport security scanner must be well grounded. The equipment socket used at the installation site must have a ground terminal.

6) If there is an area where the voltage fluctuation exceeds the regulation, it is recommended to use an AC voltage stabilizer.

7) Do not connect any electronic components that are not part of the X-ray security inspection equipment to the power distributor of the X-ray baggage inspection equipment.

8) Any improper modification may damage the X-ray baggage. Users are prohibited from making inappropriate changes to the equipment.

9) The x ray security scanner machine can only be used to inspect items, and it is strictly prohibited to inspect humans or animals.

10) It is forbidden to sit or stand on the conveyor belt.

11) Do not touch the edge of the conveyor belt and the roller.

12) When the equipment is running, no part of the body should enter the inspection channel.

13) Make sure that the baggage is not stacked in the inspection channel or at the exit end. If the baggage blocks the inspection channel, it should be pressed the emergency button to stop the belt running and shut down before cleaning.

14) The equipment cannot be operated with a damaged lead curtain.

15) Prevent all kinds of liquids from flowing into the equipment. If this happens, please shut down immediately.